With Max Corr™, installation is straightforward, thanks to their precision engineering which guarantees a snug fit. This reliability is crucial in regions prone to extreme weather, offering peace of mind with their superior resistance to wind uplift and water penetration. In addition to their aesthetic and functional benefits, these fasteners are also designed with sustainability in mind. Manufactured using high-quality materials that are both durable and recyclable, they contribute to a more eco-friendly construction process. Choosing Max Corr™ exposed fasteners means investing in a product that upholds the highest standards of quality and innovation, ensuring that your roofing projects not only stand out but also stand the test of time.

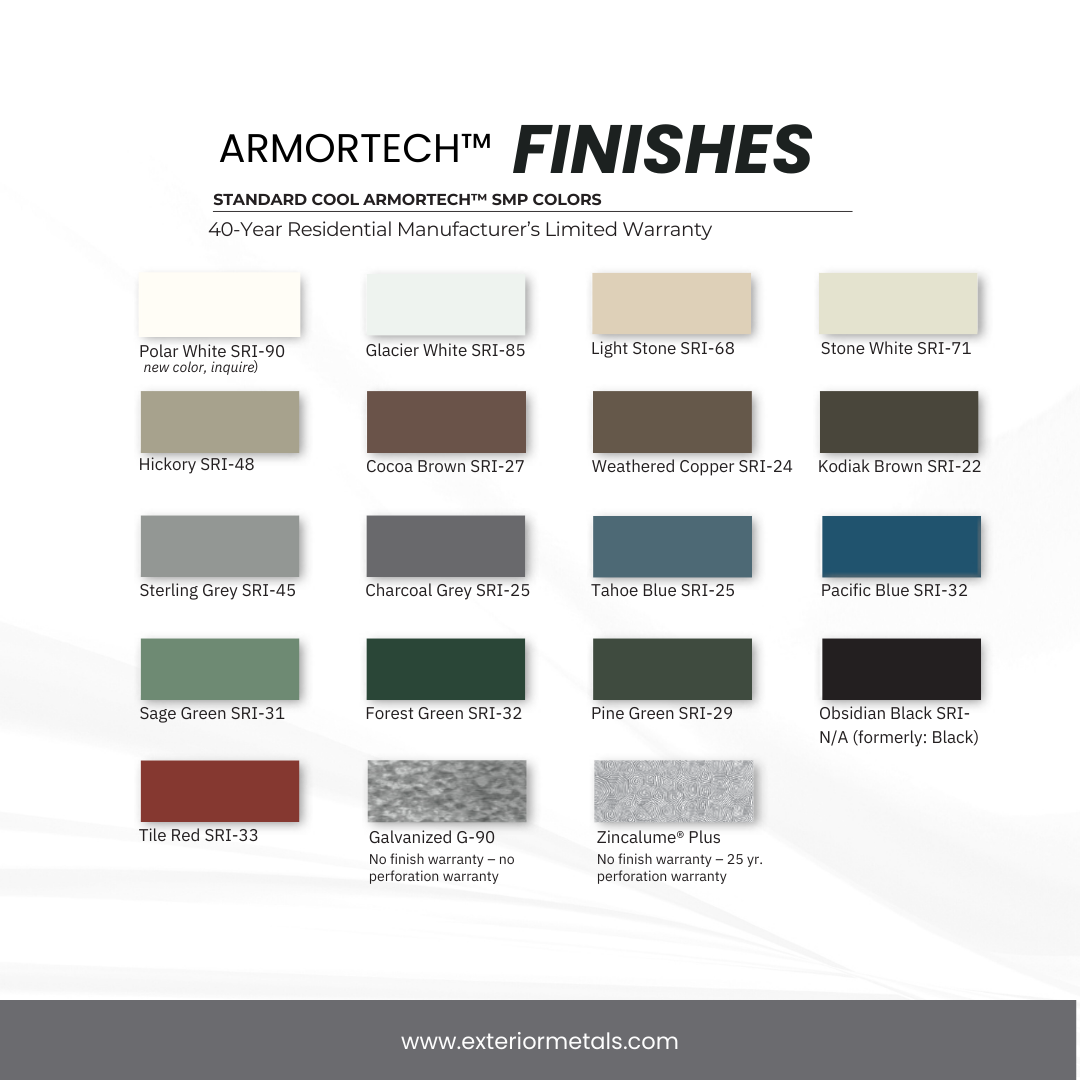

MATERIAL SPECIFICATIONS

• 24 Tru-Gauge™ Kynar 500® Painted Steel

.0236” (Thickness prior to painting)

• 22 Tru-Gauge™ Kynar 500® Painted Steel .029” (Thickness prior to painting)

• ✦ .032” Kynar 500® Painted Aluminum

• 24 Tru-Gauge™ G-90 Galvanized or AZ-50

• 24 and 22 Tru-Gauge™ bare Zincalume® Plus

AZ-55 (No finish warranty – 25 yr. perforation warranty)

• G-90 Galvanized or AZ-50

• .032" & .040” Kynar 500® Painted Aluminum

• 24 Tru-Gauge™ Bonderized

• 22 gauge Rusteel Plus™ (A606) (No finish warranty – no perforation warranty)

• Kynar 500® and substrate testing data available